Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

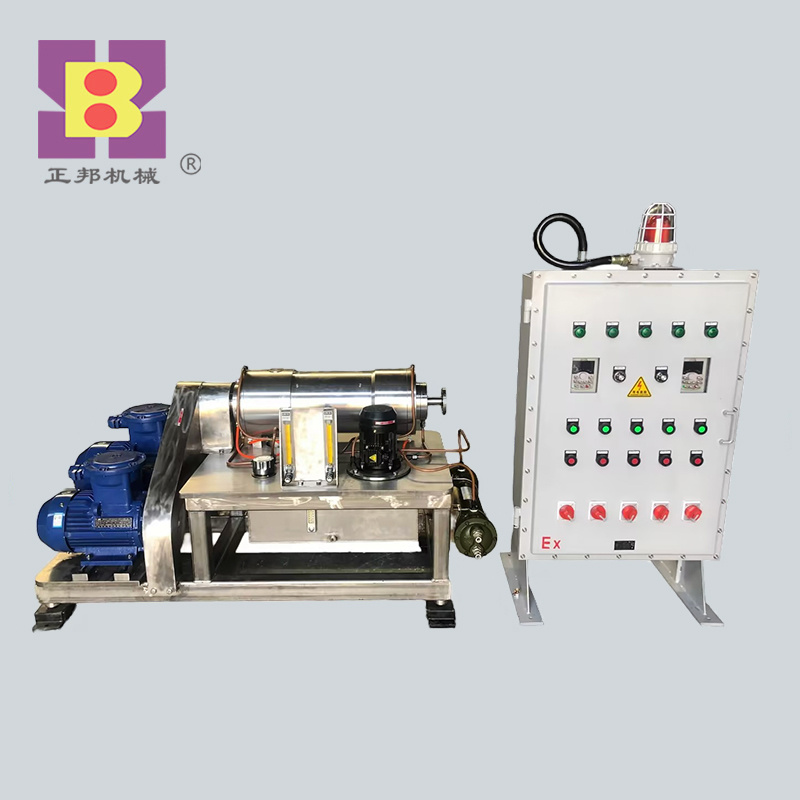

ZB-LW120 explosion-proof

Category:

Product Description

Small horizontal spiral sedimentation centrifuge

ZB-LW series small high-speed horizontal screw sedimentation centrifuge is specially designed and manufactured for solid-liquid separation of two-phase materials in laboratories, biopharmaceuticals, small chemical industries, etc. It is mainly used for continuous processing of small-displacement materials from 1L/H to 800L/H. The minimum processing capacity is much smaller than that required by industrial centrifuges. It can be used as the best separation equipment for research and development units and places requiring small-displacement material separation.

Scope of application:

ZB-LW series small high-speed horizontal screw sedimentation centrifuge are commonly used in the research and development departments of the food fermentation industry, dye industry, chemical pharmaceutical and biotechnology industries. This series of centrifuges is also suitable for producing high-quality materials with a flow rate of less than 800L/H

The ZB-LW series can also be used as a measuring instrument to record the two-phase flow characteristics of the tested product, as well as the torque changes and power consumption of the spiral, and to modify the process from the flow behavior of the product

Technical Parameters:

Model | Drum diameter | Maximum rotational speed | Separation factors | Processing capacity | Motor power | Boundary Dimensions | Overall weight |

mm | r/min | G | L/H | kw | mm | kg | |

ZB-LW80 | 80 | 10000 | 4476 | 1-200 | 4 | 1050×650×750 | 380 |

ZB-LW120 | 120 | 8000 | 4300 | 250-500 | 5.5 | 1250×750×850 | 480 |

ZB-LW180 | 180 | 8000 | 6450 | 400-800 | 5.5 | 1650×450×750 | 680 |

Note: 1. The data provided in this table are for reference only;

2.The centrifuge structure and technical parameters can be specially designed and manufactured according to the specific material requirements of users;

3.The component materials in contact with materials can be made of 304, 316L stainless steel, titanium alloy, Hastelloy, and other materials according to user needs.

Keywords:

Related Products

Welcome your message consultation